- #REFLOW SOLDERING MACHINE PRO#

- #REFLOW SOLDERING MACHINE SOFTWARE#

- #REFLOW SOLDERING MACHINE PROFESSIONAL#

- #REFLOW SOLDERING MACHINE SIMULATOR#

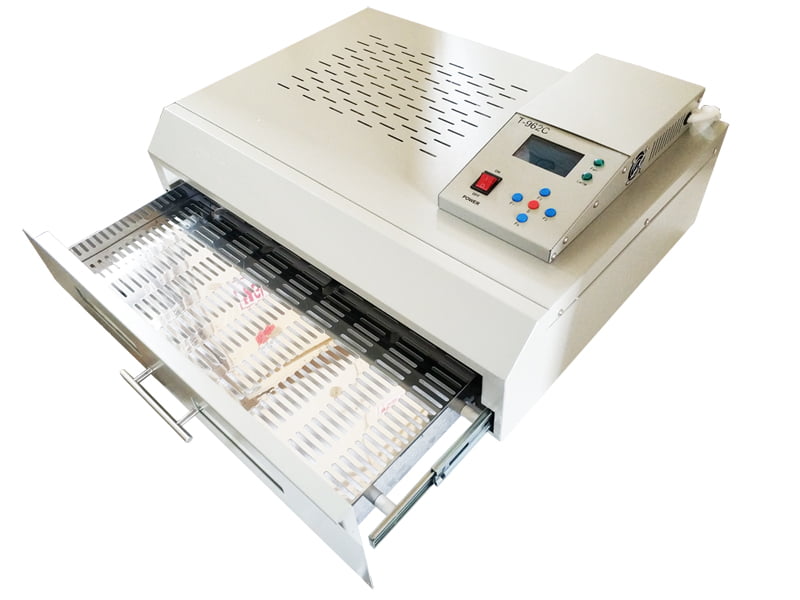

Increased productivity, superior performance and ease of operation make the PRO 1600 a versatile system ideal for small to medium run production, prototyping, NPI, testing or curing. An optional Video Recording and Observation Module allows taking high magnification images and recording video during a soldering cycle.

With the optional External Thermocouple Control ( ETC), profiles may be processed based on temperature readings of the assembly, not the air temperature around it. Even for prototypes, this often means avoiding to spend hours of testing and debugging failed boards.

Maintaining a low delta T across all of the components on the assembly ensures that they are not overheated or thermally stressed.

#REFLOW SOLDERING MACHINE SOFTWARE#

Precise software control delivers unsurpassed temperature uniformity. Where other batch and conveyor ovens fail to meet the desired profile curve, PRO 1600 excels. It offers a unique On-The-Fly settings adjustment capability that allows creating and optimizing profiles all in a single pass. Sealed heating chamber enables ramp up rates of up to 4° Celsius/second from ambient and programming of up to 10 profile zones. PRO 1600 is very user friendly in terms of profile creation and modification. It has been designed for reflow soldering of even the most challenging applications including metal core, high thermal mass, RF / microwave housings, wafer boards, and ceramic assemblies. PRO 1600 is a forced air / nitrogen convection reflow oven with a small footprint measuring only 31″ x 31″ (80cm x 80cm). We are happy to discuss your soldering oven requirements in detail, and will gladly come up with realistic solutions for your team so you can begin soldering circuit boards with detailed precision today! If you would like to get in touch with our expert soldering circuit board and soldering oven team, give us a call for more information.

#REFLOW SOLDERING MACHINE SIMULATOR#

Compatible with a variety of custom coupons and requiring minimal operator involvement, our reflow simulator provides ultra-accurate data reports and assembly analysis with simplicity. With PCB soldering machines and SMT reflow ovens designed to last, our superlative products are the perfect addition to your business for all of your soldering furnace needs.īeyond the extensive soldering circuit board and soldering oven solutions we provide, we also produce a reflow simulator for advanced microvia and IPC D coupon testing.

#REFLOW SOLDERING MACHINE PROFESSIONAL#

Our professional technicians offer complete reflow soldering machines and prototype reflow oven installation, calibration, and guidance. With on-the-fly profile adjustment, clear imaging and video options for direct monitoring, and ultra-accurate temperature control at the circuit assembly, our reflow oven is expediting process development and improves yields. Thanks to our advanced software integration, combined with precise component alignment, our SMT reflow oven achieves the user-friendly end goal. Our team wanted to create an SMT oven catering to the end user with a simplified setup and ease of operation. Our reflow ovens aim to bridge this gap with consistent heating profiles, a simple user interface, and detailed data for complete transparency and consistency throughout the SMT ( Surface Mount Technology) reflow process. While many reflow ovens on the market are adequate for simple soldering projects, without precise temperature monitoring at the circuit assembly, or the ability to displace oxygen with nitrogen within the reflow chamber, strong and reliable solder joints are not guaranteed. Our expert engineers and designers developed the PRO 1600 SMT Reflow Oven to solve a variety of common issues associated with inconsistent reflow soldering. Dedicated to quality engineering and superior service, our precise soldering machines and reflow ovens achieve predictable results you can count on. As a leading batch soldering machine and solder reflow manufacturer, we are on a mission to provide reliable solutions for the ever-evolving demands within the printed circuit board industry. After 35 years of industry-defining research and development, ATCO has developed the PRO 1600 SMT Reflow Oven.

0 kommentar(er)

0 kommentar(er)